En Exlabesa queremos hacer del aluminio una solución que permita al mundo darle la forma que necesita, descubriendo nuevos caminos para la arquitectura, haciendo que lo imposible sea más posible.

Sistemas

Proyectos

Support Hub

Exlabesa 360

Ingeniería y Desarrollo

DAP

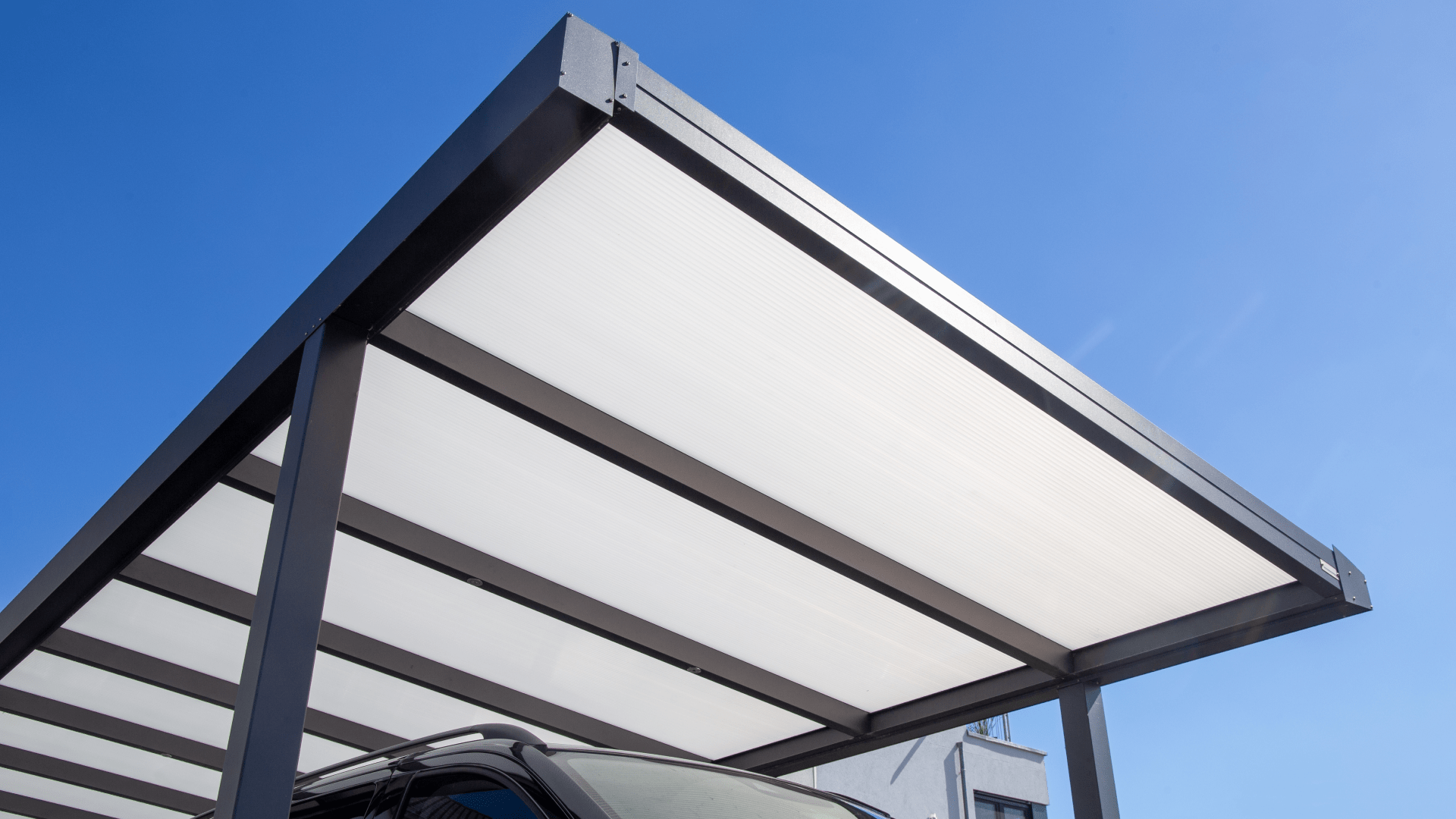

Descubre nuestra gama de sistemas de carpintería de aluminio: ventanas y puertas, muro cortina, protección solar y barandillas de vidrio

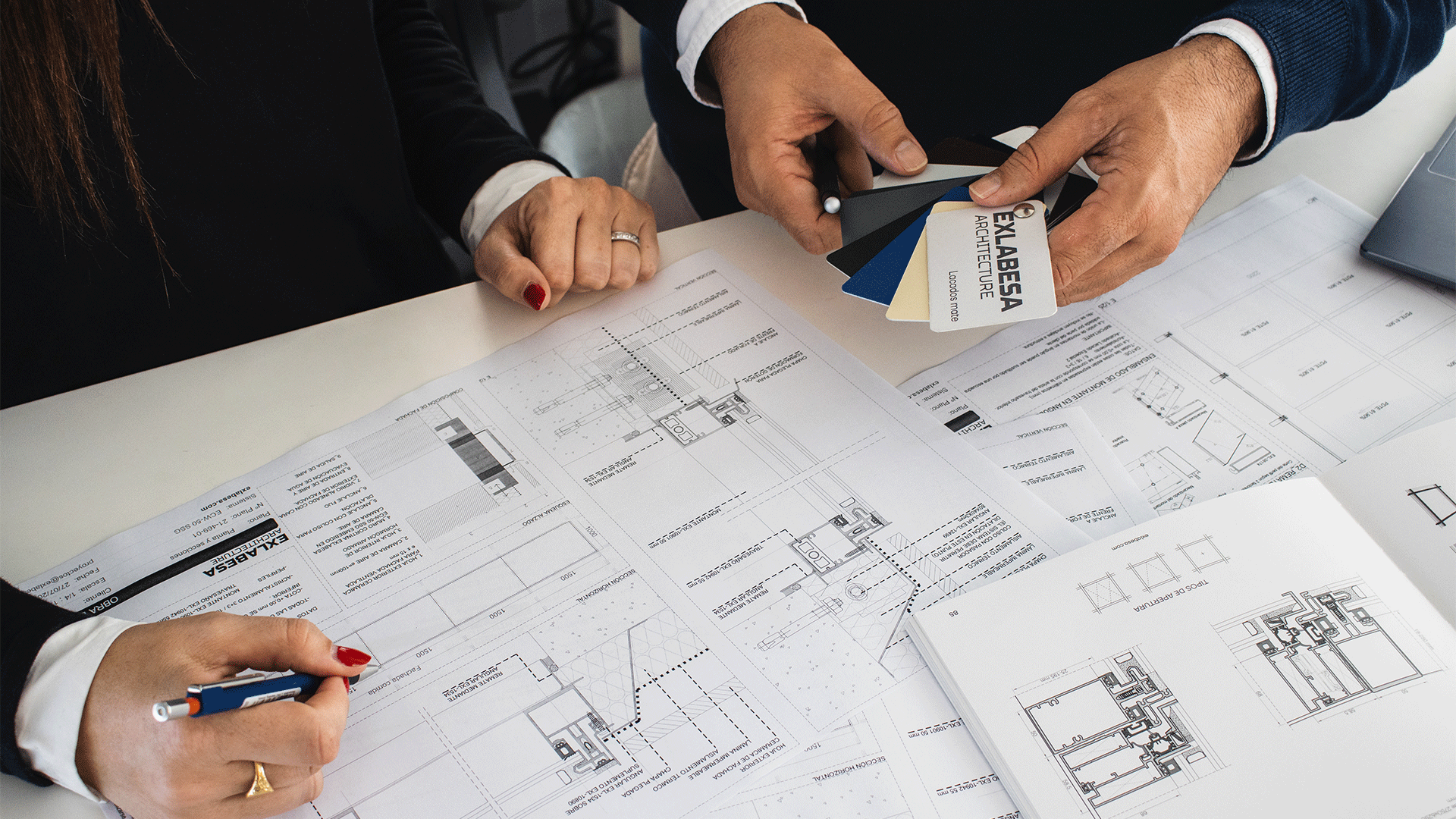

Desde la fase de ideación a la ejecución de obra, descubre todos los servicios y herramientas que ponemos a tu disposición

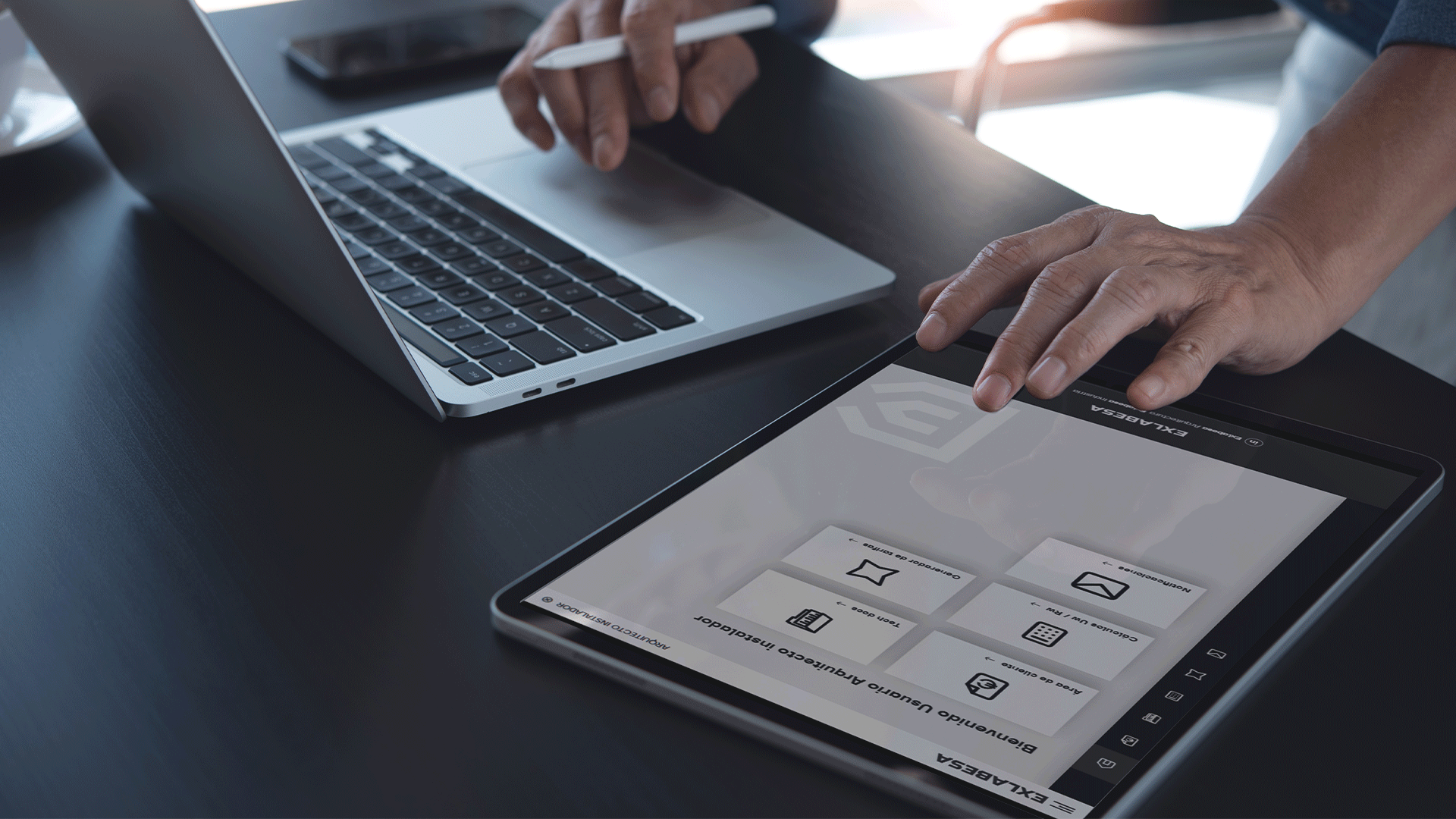

Todas las herramientas y recursos documentales necesarios para tu proyecto, donde y cuando quieras

Nuestro equipo de ingeniería y desarrollo, junto a nuestro centro tecnológico nos permite ofrecer soluciones adaptadas a las nuevas necesidades del sector

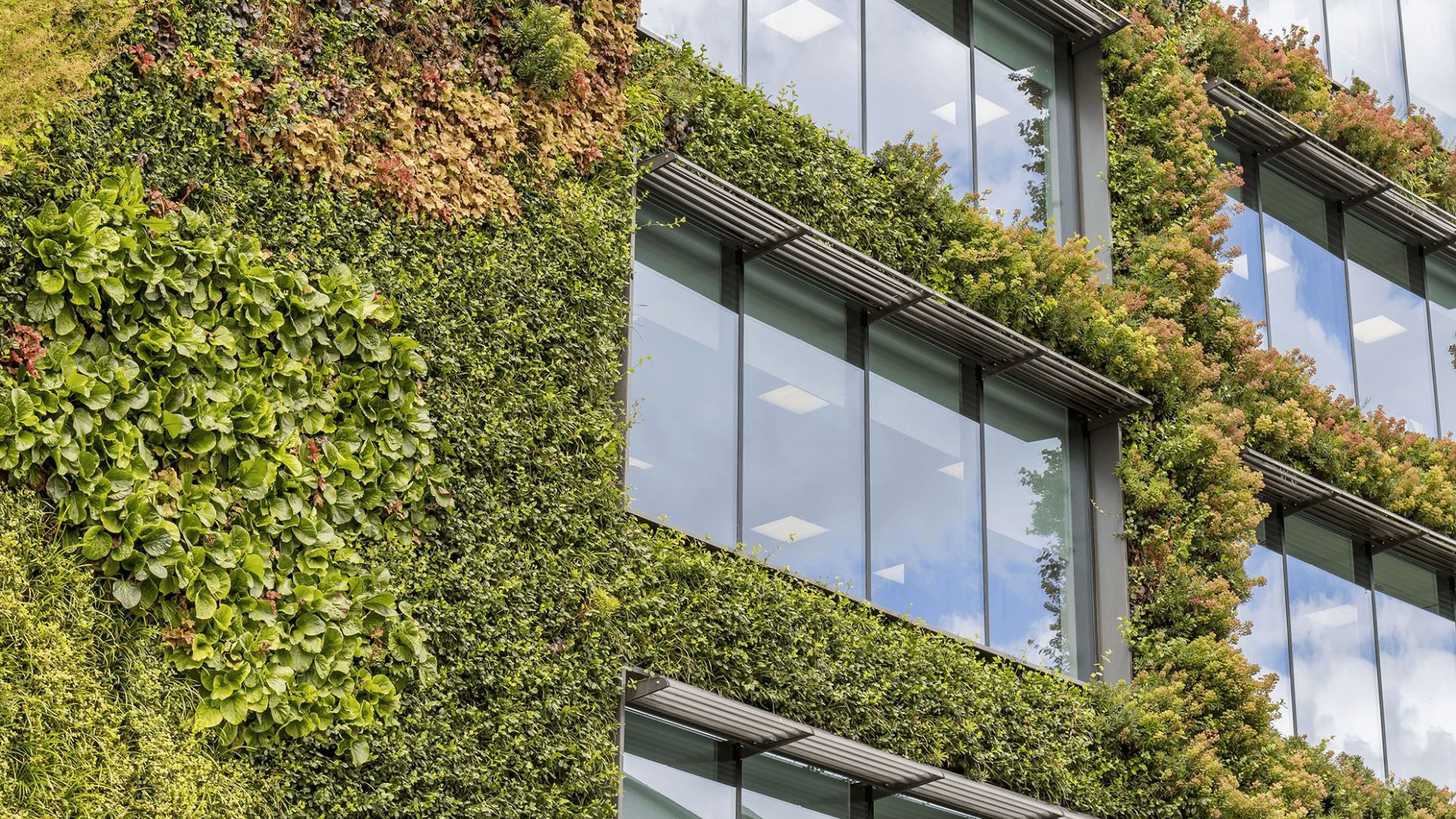

Toda la información sobre nuestras ecoetiquetas y cómo lograr, a través de nuestros sistemas, edificios sostenibles

Sistemas

Descubre nuestra gama de sistemas de carpintería de aluminio: ventanas y puertas, muro cortina, protección solar y barandillas de vidrio

Support Hub

Desde la fase de ideación a la ejecución de obra, descubre todos los servicios y herramientas que ponemos a tu disposición

Exlabesa 360

Todas las herramientas y recursos documentales necesarios para tu proyecto, donde y cuando quieras

Ingeniería y Desarrollo

Nuestro equipo de ingeniería y desarrollo, junto a nuestro centro tecnológico nos permite ofrecer soluciones adaptadas a las nuevas necesidades del sector

DAP

Toda la información sobre nuestras ecoetiquetas y cómo lograr, a través de nuestros sistemas, edificios sostenibles

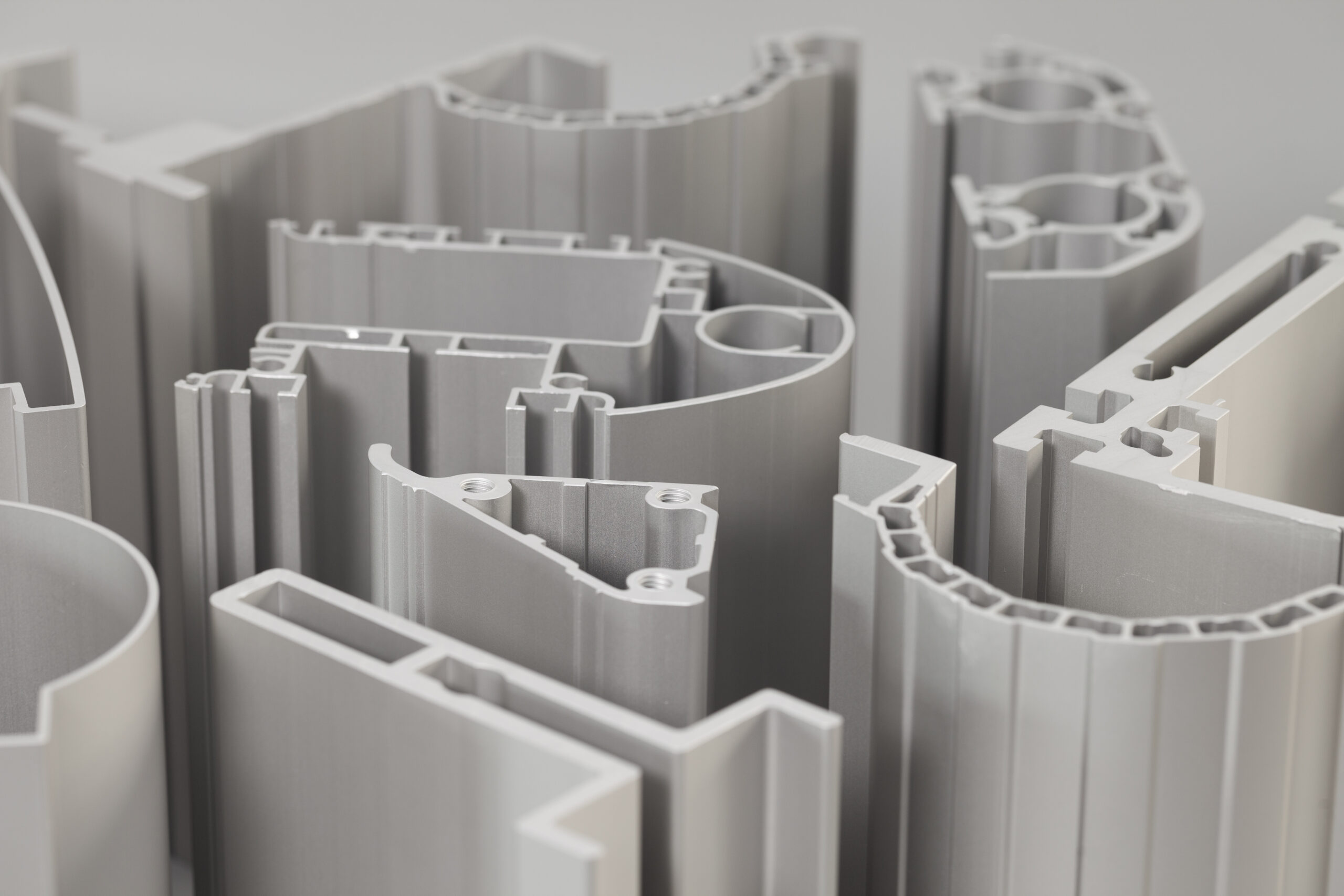

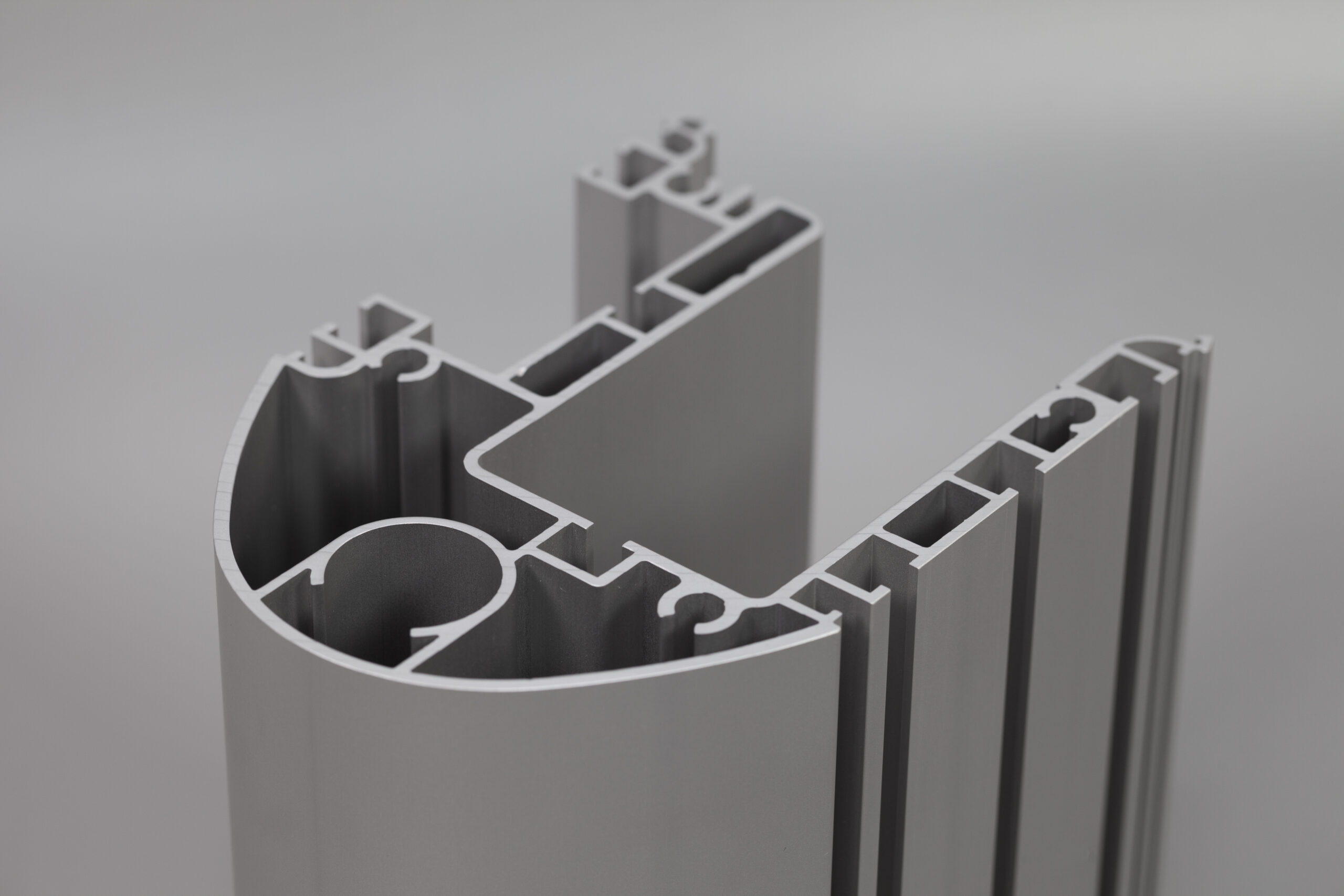

Extrusión de perfiles: hacemos realidad las necesidades, sueños y aspiraciones de quienes nos rodean, inspirando nuevas posibilidades, extruyendo y dando formas imposibles al aluminio, con la capacidad de un gigante y la precisión de quien cuida los detalles, para ayudarte a llegar donde nadie ha llegado antes.

Productos

Sectores de actividad

Localizaciones

Procesos

Calidad

Aluminio

Descubre en detalle toda la variedad de productos de aluminio que podemos fabricar con nuestras capacidades productivas. Ofrecemos perfiles de aluminio de alto valor añadido

Descubre porqué el aluminio es uno de los materiales de mayor calidad y versatilidad para multitud de aplicaciones industriales

Estamos cerca de ti para poder llegar donde nadie ha llegado antes. Conoce cada uno de nuestros centros de producción

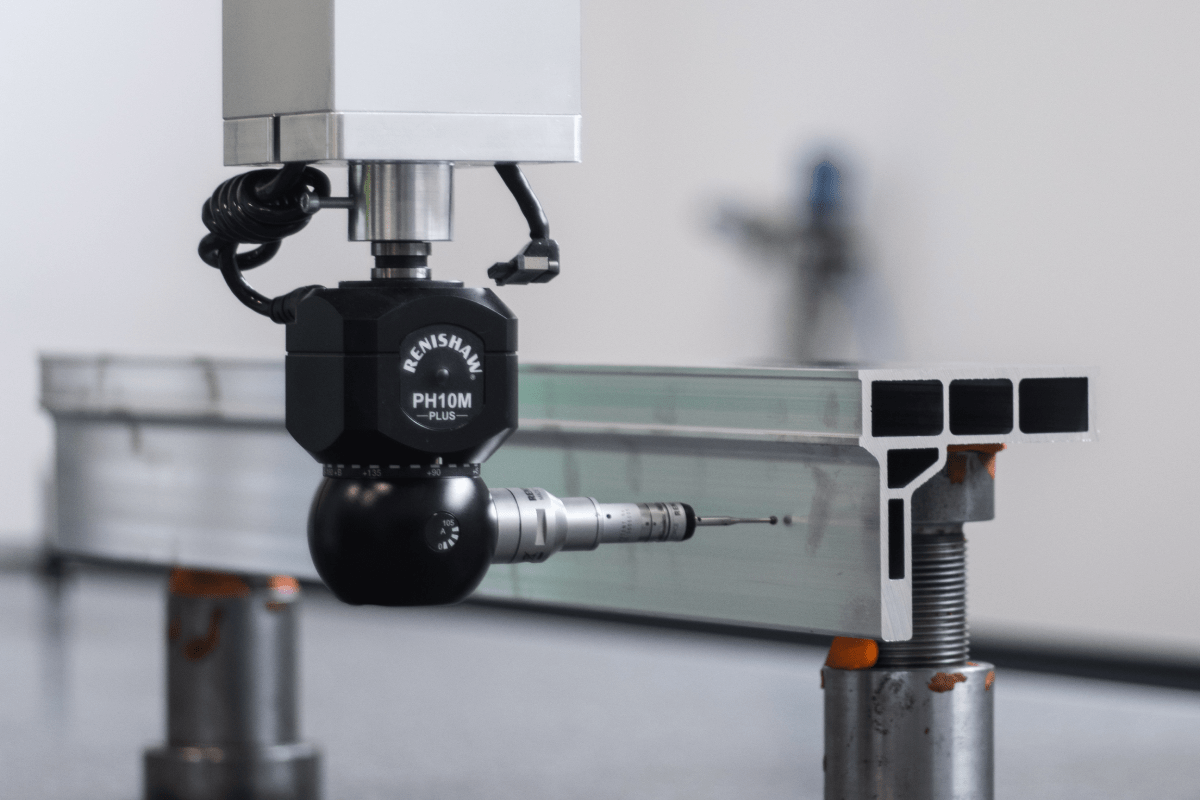

Eficiencia y precisión junto a la última tecnología en la fabricación de perfiles de aluminio. Somos el impulso que necesitas para alcanzar tus metas

La mejora continua tanto de los procesos como de los productos es una de la base fundamental nuestro sistema de producción

Descubre como el aluminio forma parte de nuestras vidas gracias a sus inigualables propiedades técnicas y decorativas

Productos

Descubre en detalle toda la variedad de productos de aluminio que podemos fabricar con nuestras capacidades productivas. Ofrecemos perfiles de aluminio de alto valor añadido

Sectores de actividad

Descubre porqué el aluminio es uno de los materiales de mayor calidad y versatilidad para multitud de aplicaciones industriales

Localizaciones

Estamos cerca de ti para poder llegar donde nadie ha llegado antes. Conoce cada uno de nuestros centros de producción

Procesos

Eficiencia y precisión junto a la última tecnología en la fabricación de perfiles de aluminio. Somos el impulso que necesitas para alcanzar tus metas

Calidad

La mejora continua tanto de los procesos como de los productos es una de la base fundamental nuestro sistema de producción

Aluminio

Descubre como el aluminio forma parte de nuestras vidas gracias a sus inigualables propiedades técnicas y decorativas